Ask a Conveyor Expert: What’s a common mistake people make when planning a Conveyor System?

Featuring: Derek Lawrence, Sales Rep at BID Canada

When it comes to planning a material handling system, most people zero in on the conveyor itself—belt specs, capacity, incline, and how fast it can move product from A to B. But according to Derek Lawrence, Sales Rep at BID Canada, that’s just one piece of the puzzle. “The biggest mistake we see is customers focusing on the conveyor, but not what’s around it,” says Derek. “Access, transfer points, maintenance clearance, even how materials are fed onto the belt—those details can make or break a project.”

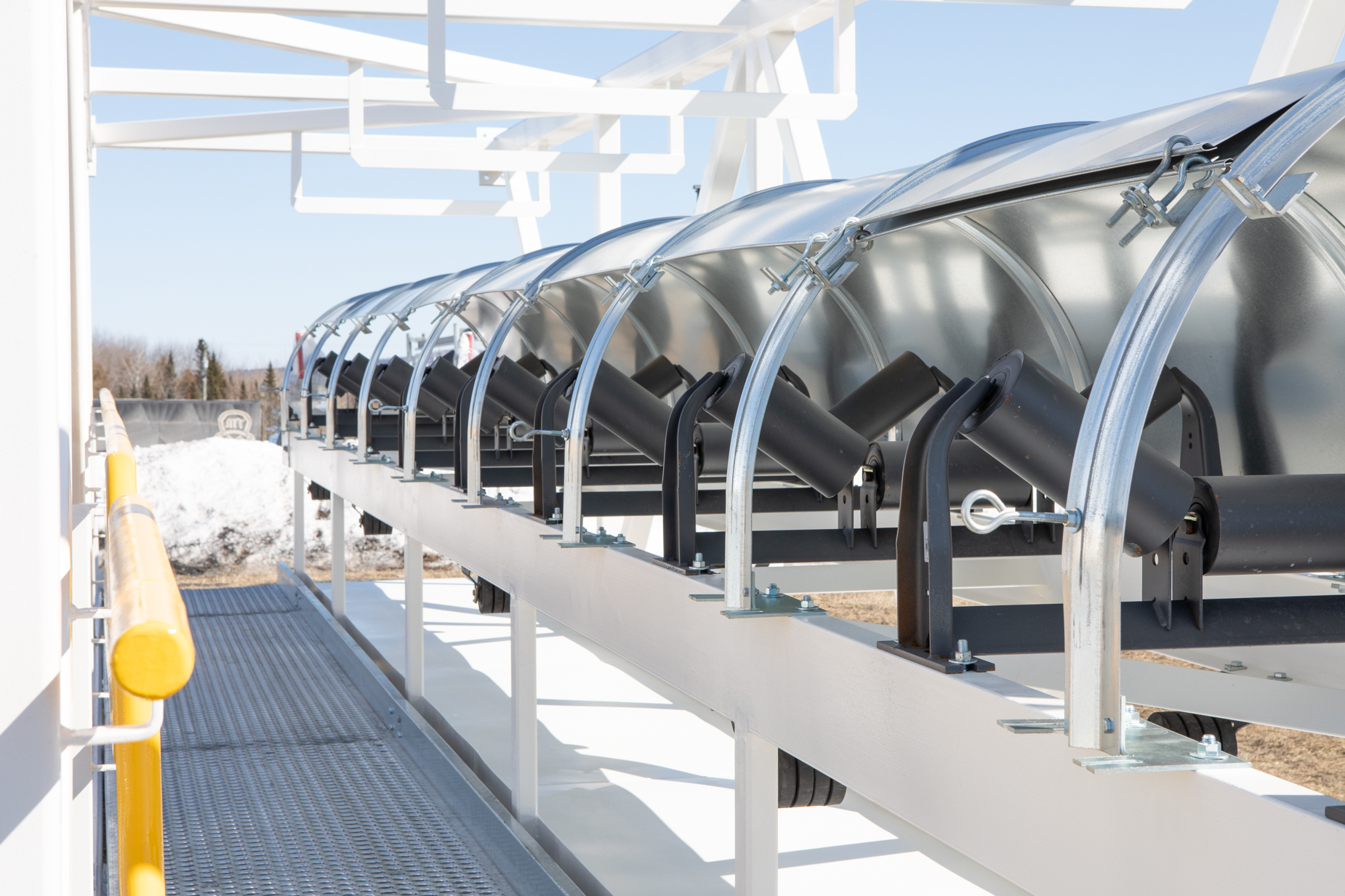

It’s About the Whole System, Not Just the Belt

A conveyor system doesn’t live in a vacuum. It interacts with equipment upstream and downstream. And it has to live inside your physical space—around support beams, electrical lines, operators, and safety walkways. “I’ve visited sites where everything looked perfect on paper, but when the equipment arrived, there wasn’t enough clearance to change out a bearing, or no safe way to inspect a chute,” Derek explains. “That’s where experience matters.”

What to Think About Early

Derek recommends considering these before you finalize a system layout:

- Will your team have safe, regular access for maintenance?

- Are your transfer points designed to reduce spillage and wear?

- Does your layout allow room for future equipment or extensions?

- Are you building around existing infrastructure that may cause a bottleneck?

Even something simple—like the direction of belt travel or the location of controls—can have a major impact on long-term usability.

We’re Here to Help You Think it Through

At BID, our team has designed and built custom material handling systems across mining, forestry, aggregates, and industrial sectors. We know what questions to ask—because we’ve seen what can go wrong. “We’d rather help you before a problem starts,” says Derek. “And we don’t just design conveyors—we design solutions that fit.”

💬 Got a challenge you’re working through?

Our experts are here to talk shop, offer input, or help you scope a project from the ground up.

📩 Ask us anything—we’ll get you moving.